Leading Attributes to Seek in High-Quality Industrial Scales

In the world of industrial procedures, choosing the right scale is essential for making sure efficiency and precision. Secret features such as precision and precision, along with durability and develop quality, play a substantial role in determining the suitability of a range for specific applications.

Accuracy and Precision

Guaranteeing the precision and precision of industrial ranges is critical for reliable operations throughout various fields. Accurate measurements are critical in markets such as production, logistics, and food processing, where also small inconsistencies can bring about significant monetary losses, endangered product high quality, or governing non-compliance. Top quality commercial ranges are developed to provide reliable performance, using innovative modern technology to guarantee exact weight analyses.

The calibration process is important in preserving the precision of these ranges. Regular calibration against accredited referral weights makes certain that any drift in measurement is fixed, thus maintaining compliance with market criteria. In addition, using high-resolution lots cells boosts the scale's capability to detect minute weight changes, even more enhancing its precision.

Durability and Construct Quality

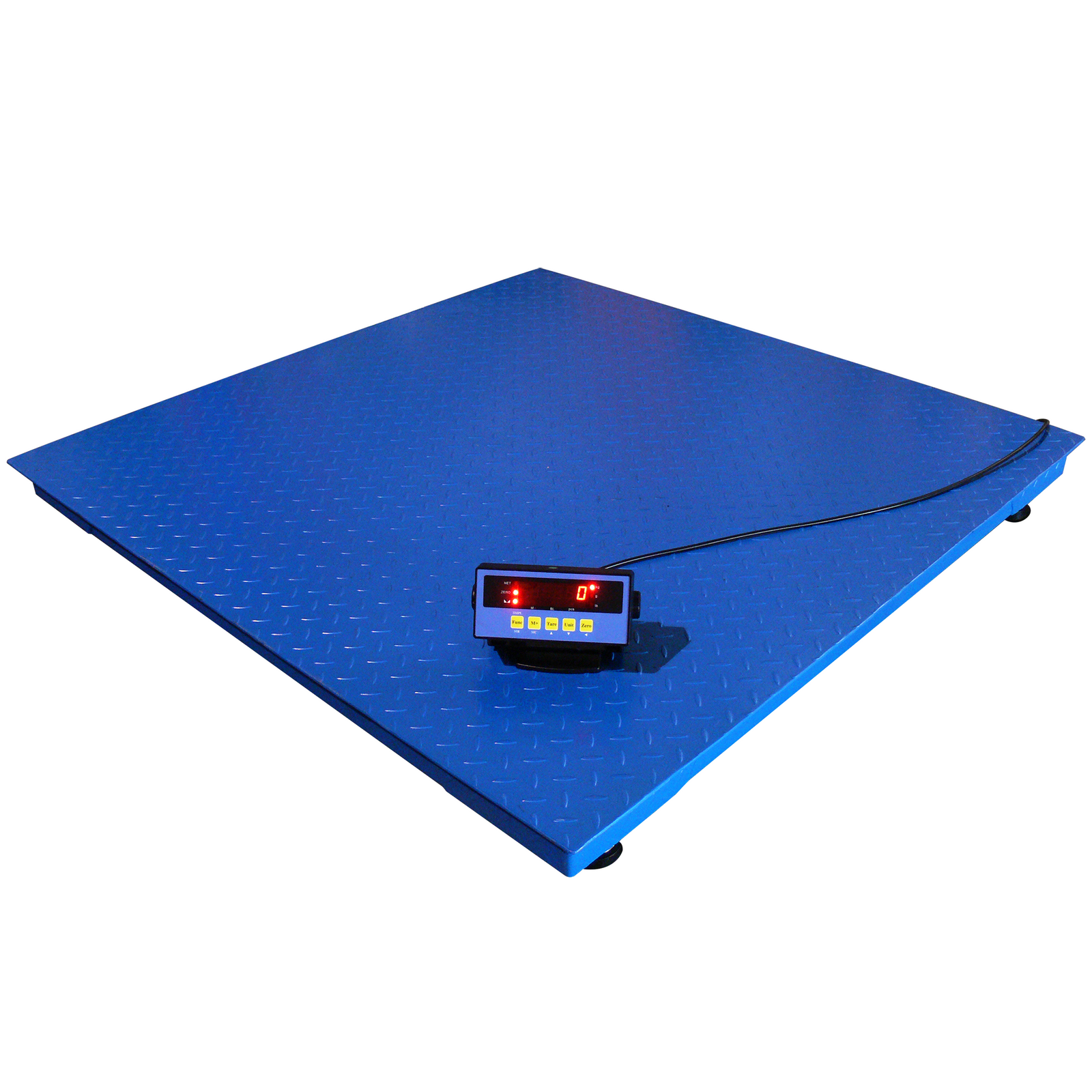

Resilience and develop high quality are important variables that establish the long life and integrity of industrial ranges in requiring settings. Industrial ranges are usually subjected to rough problems, consisting of direct exposure to dust, wetness, and heavy lots. Therefore, the materials used in their building and construction play a vital duty in guaranteeing they can hold up against these obstacles.

Top quality industrial ranges normally include robust real estates made from materials such as stainless steel or light weight aluminum, which not just offer architectural honesty however also stand up to rust and wear. Furthermore, attention to detail in the design, such as strengthened edges and shock-absorbent feet, can improve sturdiness and safeguard delicate elements from damages.

Moreover, high-grade parts, including load cells and electronic components, contribute to the total develop quality. These components should be created to tolerate temperature level fluctuations and resonances typically located in industrial settings. Ensuring appropriate ingress security (IP ranking) is likewise vital, as it suggests the range's ability to stand up to dust and liquid exposure.

Inevitably, selecting commercial ranges with exceptional durability and develop high quality will certainly result in a much more reliable, resilient remedy that meets the extensive demands of numerous industrial applications.

Lots Ability and Array

When choosing industrial ranges, comprehending their lots capacity and array is important for conference specific operational requirements. Tons ability describes the maximum weight that a scale can precisely determine, while the array shows the spectrum of weights the scale can handle successfully. It is crucial to choose a range that not only meets present demands but additionally fits prospective future demands.

Various sectors have unique weight dimension needs. A manufacturing center may need scales qualified of considering heavy machinery elements, while a research laboratory could just require ranges for lighter materials. Picking a scale with a suitable lots capacity makes certain precision and accuracy, stopping overwhelming that might cause devices damages or incorrect analyses.

In addition, it is very important to take into consideration the step-by-step sensitivity of the scale within its range. A scale that can measure both light and hefty weights accurately can enhance functional effectiveness, enabling for flexible applications. Purchasing ranges with suitable load ability and variety dramatically adds to efficiency, compliance with industry standards, and general operational integrity. Comprehensive analysis of these specs is vital prior to purchase.

Simplicity of Usage and Maintenance

In enhancement to user-friendliness, convenience of maintenance is an additional essential element to take into consideration. Scales that are made with obtainable elements help with routine upkeep tasks such as cleaning, battery, and calibration substitute. A modular layout can even more improve these procedures, allowing for fast repairs and minimal downtime.

In addition, the materials utilized in the construction of industrial ranges play a significant duty in maintenance. Ranges made from durable, corrosion-resistant materials are less complicated to tidy and less susceptible to damage, which extends their life-span and reduces general functional prices.

Normal maintenance routines, directed by the manufacturer's recommendations, are crucial for ensuring optimum performance. By prioritizing simplicity of use pop over to these guys and upkeep, organizations can guarantee that their commercial scales stay effective, trustworthy, and reliable devices in their procedures. This leads to boosted performance and a more efficient workflow.

Connectivity and Integration Options

Integrating commercial scales into existing operational frameworks is significantly improved by robust connection alternatives. High-grade commercial ranges must use several connection methods, including USB, Ethernet, and wireless alternatives such as Wi-Fi or Bluetooth. These features assist in smooth data transfer to main data sources, ERP systems, or cloud systems, making it possible for real-time surveillance and coverage.

Additionally, advanced integration choices permit compatibility with existing devices, such as printers or barcode scanners, improving processes and boosting process efficiency. Ranges that sustain industry-standard procedures, such as Modbus or RS-232, can easily connect with different gadgets and systems, making sure a cohesive functional atmosphere.

Another necessary element is the ability to incorporate with software application solutions that examine and visualize information - Industrial Scales. Scales geared up with APIs or software program development sets (SDKs) provide services the flexibility to personalize performances customized to their particular demands

Lastly, thinking about future scalability is crucial; selecting ranges that can adjust to progressing technical developments makes sure long-term value and minimizes the requirement visit this web-site for pricey replacements. In summary, examining connection and integration options is vital when choosing high-grade industrial scales that will improve functional performance and data monitoring.

Verdict

To conclude, selecting premium commercial ranges demands careful factor to consider of several vital attributes. Precision and accuracy make certain trustworthy measurements, while resilience and develop high quality improve durability in challenging atmospheres. Appropriate load capacity and array deal with varied sector needs. In addition, ease of use and maintenance promote functional performance, and durable connectivity choices help with smooth data integration. Focusing on these attributes eventually causes boosted efficiency and long-term value in industrial applications, reinforcing the relevance of educated decision-making in range choice.

In the world of industrial procedures, choosing the right scale is important for making sure effectiveness and precision.Making sure the accuracy and precision of commercial scales is paramount for efficient operations throughout numerous markets. Tons capacity refers to the optimum weight that a scale can precisely gauge, while the range shows the spectrum of weights the scale can handle successfully. A manufacturing facility might require scales qualified of evaluating hefty machinery click for more info elements, while a laboratory may just need scales for lighter products. By prioritizing simplicity of usage and upkeep, companies can make certain that their industrial scales continue to be effective, trusted, and effective tools in their procedures.